years of expertise

years of expertise

During the past decades we have gained all the knowledge and dexterity we can proudly offer to our clients around the globe. Cutting edge pre-production technologies as well as 3 types of foundries and variety of advanced finishing works are the reasons we will very likely meet your demanding requirements.

Future belongs to aluminium

We believe that aluminum is a metal that now has, and in the future will have, an even greater share of components without which industrial production and technology can not sustain.

That is why we use the latest production technologies that are environmentally friendly and we invest in the development of the company so that we can provide our customers with all the services (from the design of the shapes to any surface treatment or inspection) that are necessary for the proper functionality of the product.

History we are proud of

-

1991

Incorporation

Company UNITHERM, s.r.o. is registered in the Commercial Registry of the Regional Court in Ústí nad Labem, Section C, Insert No. 245.

1991–1998

Award of Prince Henrik of Denmark

Commercial, designing and implementation works for the heating plant industry including heat production operations by means of co-ownership of a heating plant company. UNITHERM becomes an exclusive sales representative of the Kamstrup company and launches their metering devices onto the Czech and Slovak market. Award of the Association of Danish Enterprises in form of a diploma and a medal of His Majesty Prince Henrik of Denmark for strengthening of business activities between both countries.

1999

Aluminium age

The company expanded its business activities by starting a foundry specialised in sand casting of aluminium products.

2000–2007

ISO certification

The foundry expanded its activities by casting aluminium products into metal moulds and also by providing other technologies, such as impregnation, heat processing of castings and sub-assemblies. Certification for ISO 9001 and 14001. The Energo Division continues building boiler rooms and other units in the area of heating plant industry.

2008

Foundry expansion

Construction of new sand casting foundry for production of heavy and large castings. The Energo division concentrates on the sales of Nivolair heating units, Oilon burners and Kamstrup energy meters. As far as the construction business is concerned, the company specialises in the designing and construction of power centres.

2010

SVTI Certification

Reliability and consistent manufacturing process make us an authorized holder of this certification. This one is mostly searched for by customers in the energy industry.

2012

Realization of casting of parts for the complete facade of the regional gallery

Decorative facade boards weigh a total of 33 tons.

2014

Launching a sand foundry using geopolymer binders

Successful completion of R&D of ecological replacement of toxic furan mixtures and construction of a new foundry.

2017

New equipment

+ New automatic heat treatment line

+ New turning machine OKUMA LB 4000 EX 2

2018

New equipment

+ New turning center KOVOSVIT MAS MCH 630

+ New machining center TAJMAC-ZPS H630

+ Sand mixing system for bentonite foundry

2019

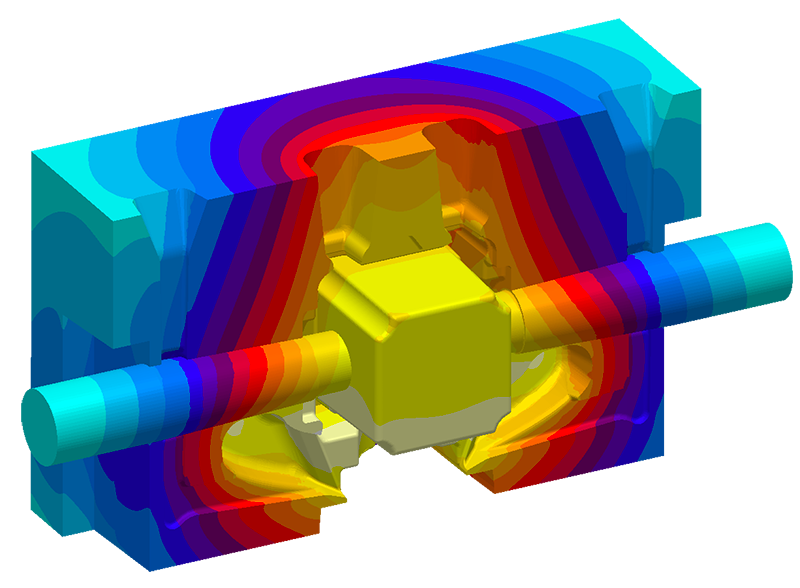

New simulation software

+ investment into simulation software MAGMASOFT® including simulation data for our geopolymer foundry especially developed and implemented by Magma for our company

2020

New grinding center

+ Koyama 500 TTA - 7 CNC axes, internal work area - Ø 800mm x 550mm height

2023

Digitalisation, innovation

+ Project for the acquisition of HW and SW to increase the digitalization of processes in the company and the introduction of a new MES system. The project is co-financed by the European Union.

+ Planned investment – purchase of melting furnaces with recuperation from LAC

Production

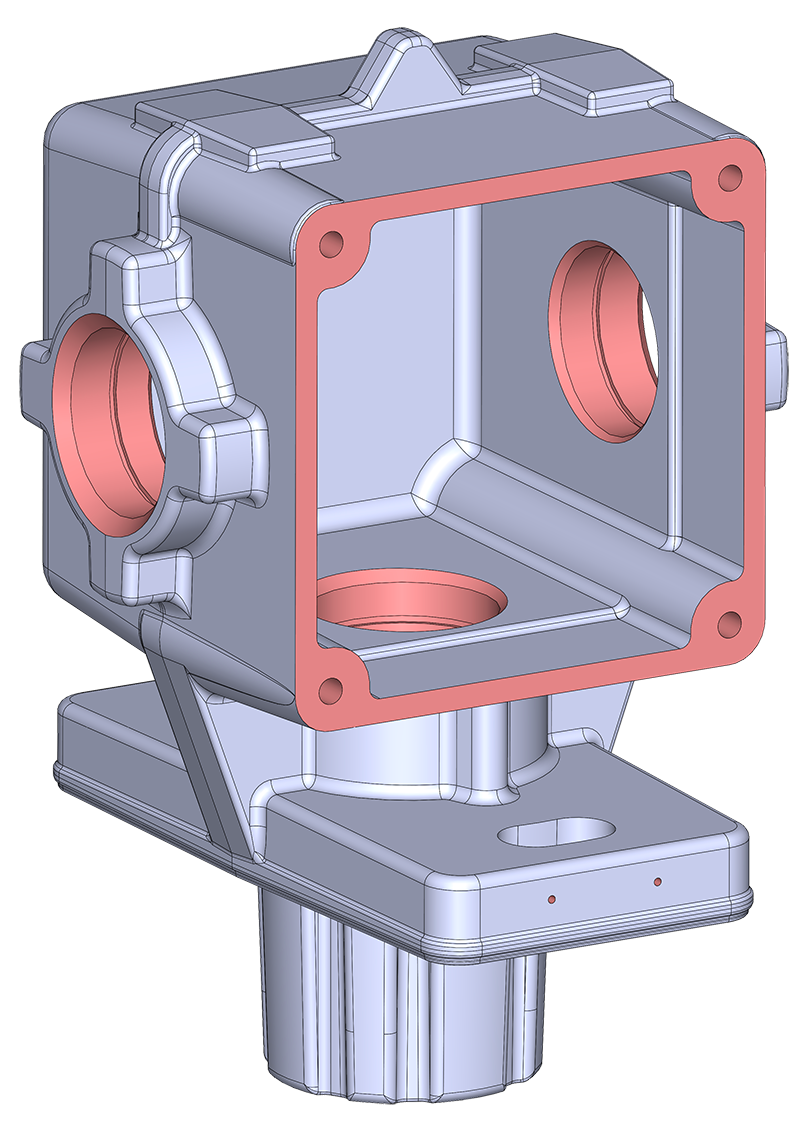

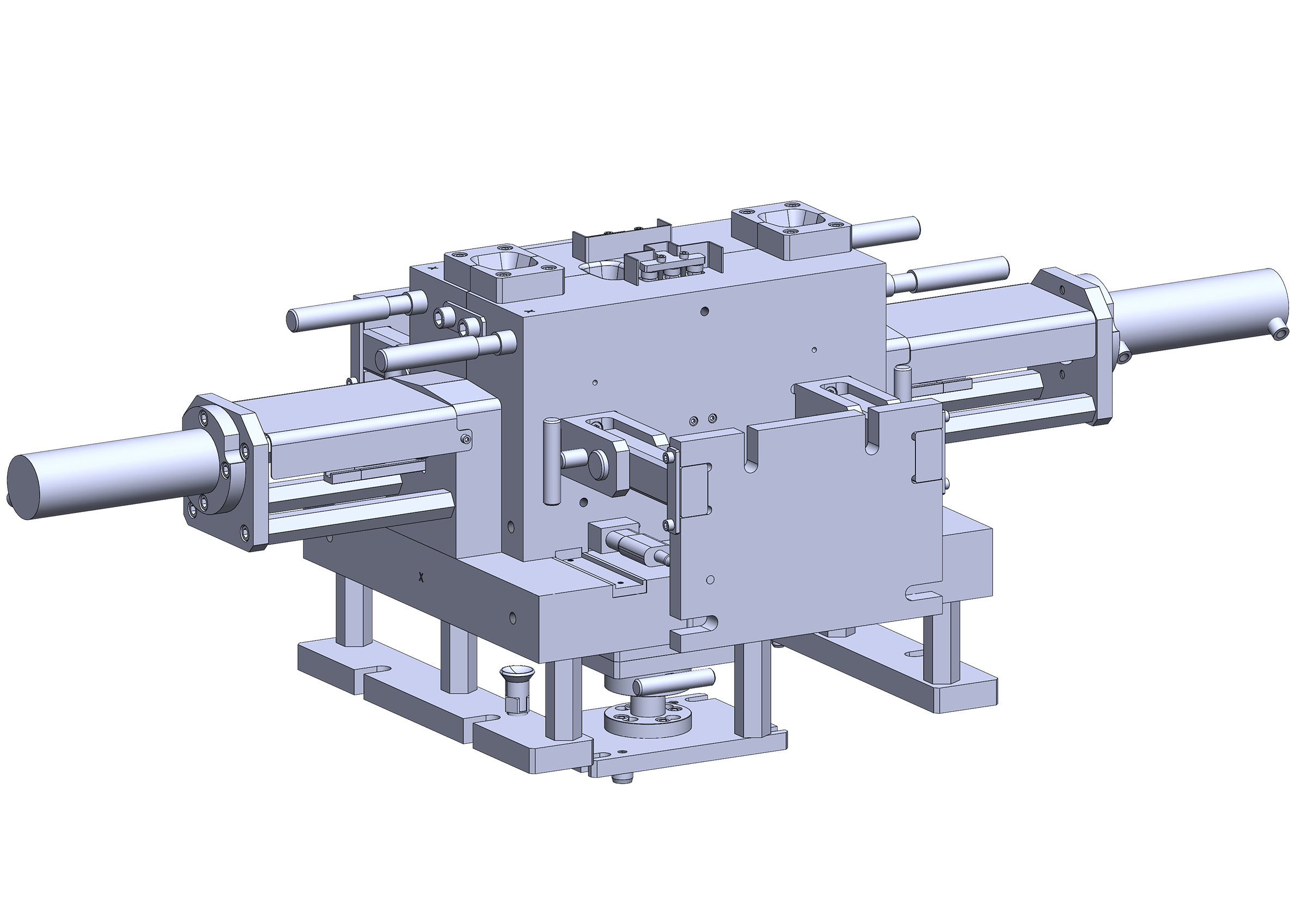

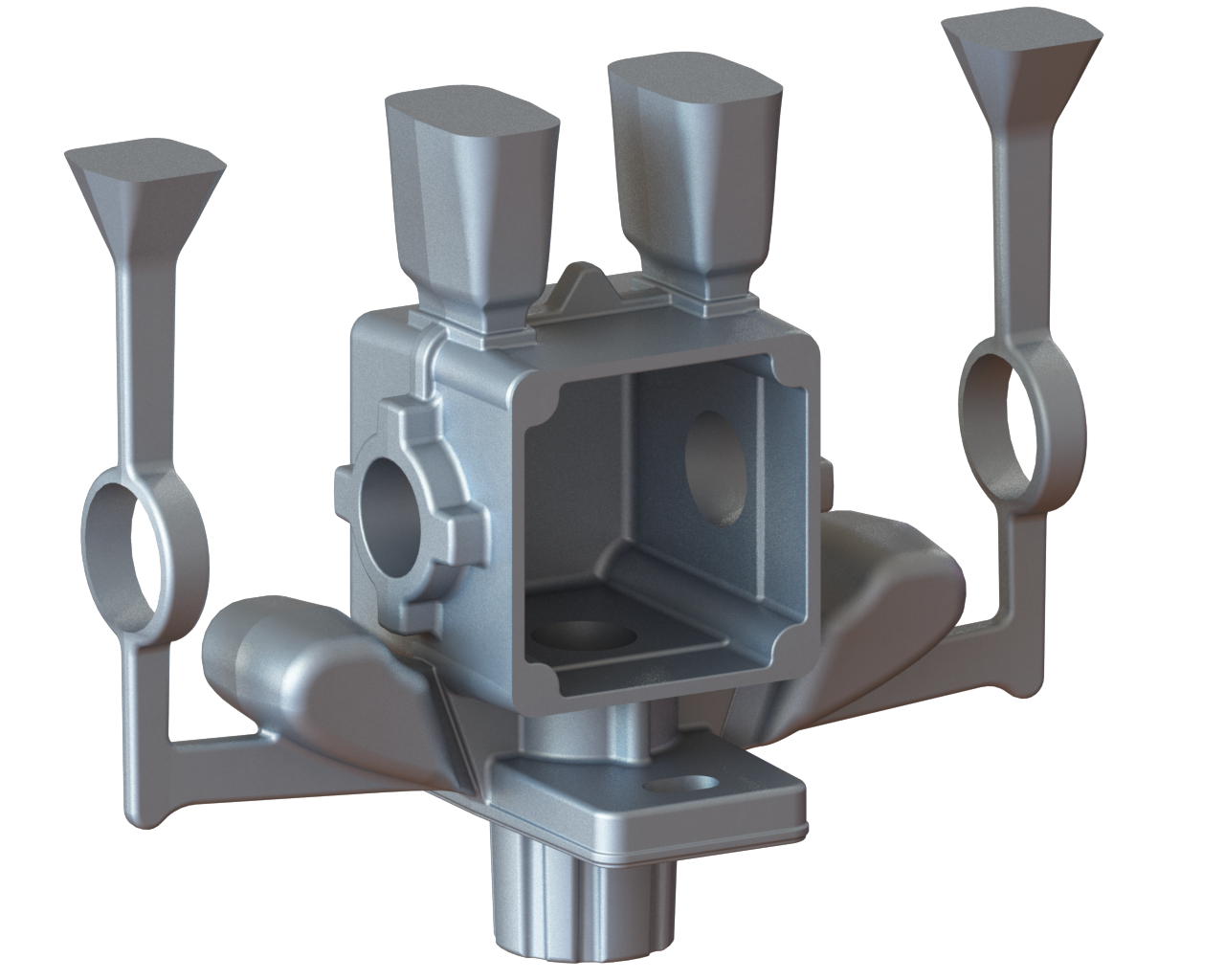

3D Construction

Simulation

The MAGMASOFT® simulation program is used to verify the correctness of the casting design and casting technology and at the same time predicts the occurrence of possible defects in the casting.

Casting

Bentonite foundry

Moulding machines: Foromat 20, 40, FRFG 20, FRFG 20

Size of frames: 400 x 300 mm – 1000 x 1000 mm, casting weight: 0,1- 100kg

HSP line: casting into sand moulds produced by machine moulding with impulsive air injection and dolly moulding with moulding frame dimensions 650 × 650 mm and casting weight 1-30kg.

Geopolymer foundry

Size of frames: max. 1200x1200 mm, casting weight: max. 150kg

Die casting Foundry

Gravity Casting: CGU, CGH, Folding casting machine, hydraulic stands - 0,1 - 20kg

Low pressure casting: semi-automated machines CNS, Kurtz - 1 - 50kg

Finishing

Modern machining workshop

TAJMAC-ZPS H630 ~ 4-axis machining centre ~ working area 750 × 700 × 770 mm

CHIRON FZ 12 WM ~ 4-axis machining centre ~ working area 400 × 300 × 300 mm

CHIRON FZ 18 WM ~ machining centre ~ working space 400 × 400 × 300 mm ~ 2x

FGSQ80 CNC ~ working area 2000 × 800 × 650 mm

FS 50 CNC ~ working space 1000 × 650 × 500 mm

HAAS ST-40 CNC ~ lathe ~ cutting diameter 648mm ~ cutting length 1118 mm

MAZAK SQT 200M ~ turning centre ~ MAZAK SQT 20 - 500V ~ turning ø 300 × 500 mm

DF 2/3 CNC ~ CNC lathes ~ turning ø 400 mm × 300 mm

OKUMA LB4000 EX-II ~ turning ø 480 x 750 mm

TOS SUA 125 ~ working area 1050 × 800 × 880 mm

Koyama 500 TTA ~ automatic grinding and cutting centre with rotary table ~ 7 CNC axes ~ internal work area Ø 800 mm x 550 mm height

Final Product

Machining shop

Quality control on three-coordinate measuring machine - Wenzel LH87, software WM Quartis

Material certification according to 3.1

Pressurizing of castings up to max. pressure of 6 bar

Heat treatment T4, T6

Blasting with chrome steel stainless granulate and corundum mixture

Tightness test using helium leakage detector

Assembly of parts

Surface treatments according of specifications - In cooperation surface treatments according of specifications

High quality we strive for

We meet the standards of quality management system for casting aluminium alloys into sand moulds, metal moulds and low-pressure moulds. We are also SVTI certified which means we are an approved supplier of products for high-voltage industries.

Environment is essential For all of us

We want to have a healthy environment around us, so we only use ecological mixtures and production materials. When introducing new technologies, we take care not to have a negative impact on the environment. Our long-standing certificates and developed technologies declare the success of our efforts.

Cast locally, export globally

78 % of our production is exported to the world. That is the proof we are able to meet the highest standards no matter if it is for the markets within European Union, North or South America or Eastern countries.

Economic data

Proving we are on a good pathway

Turnover in time in millions of euros

Partition of turnover

Industries we supply for

Total production in tons of alluminium

AlSi7Mg0,3

AlSi7Mg0,6

AlSi10Mg(a)

AlSi8Cu3

AlSi12(b)

AlSi9Cu1Mg

AlMg3

AlZn10Si8Mg

Contact us, visit us. Let’s meet in person!

And have a cup of coffee. For more information how to reach us in person, via phone or e-mail please visit our website.